What is the production process flow of tinplate

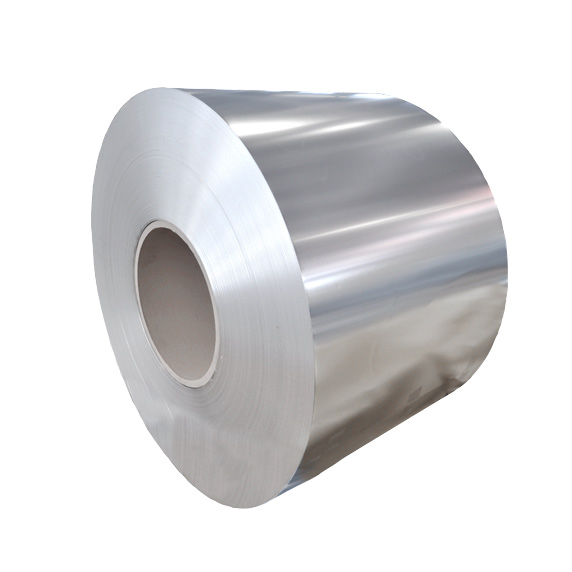

The production process of reputable tinplate includes: pickling -- cold rolling -- annealing -- leveling -- trimming -- tinning -- oiling

Pickling: 1 is for the oxide on the surface of the raw plate 2 is for the edge cutting to check whether there is a defective raw plate

Cold rolling: mainly through pressure to make its thickness thinner. This can be done at room temperature.

Annealing: This process is mainly to adjust the corresponding hardness according to the customer's use and requirements. There are two ways: 1) bell type annealing and 2) continuous annealing. The higher the normal hardness is, the more continuous annealing is used

Flatness: mainly in two aspects: 1) inspection of surface state; 2) flatness of plate type

Trimming: the minimum cutting is 5mm, and the normal cutting is 7.5mm

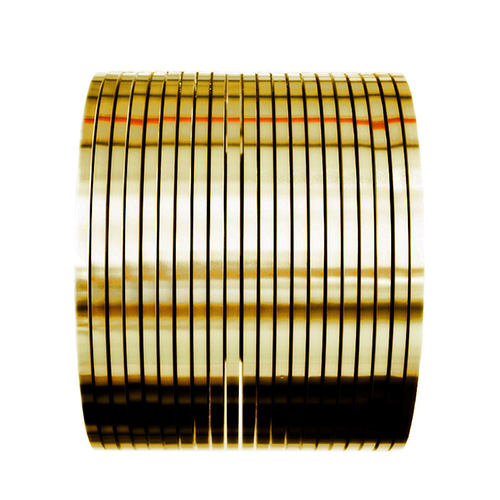

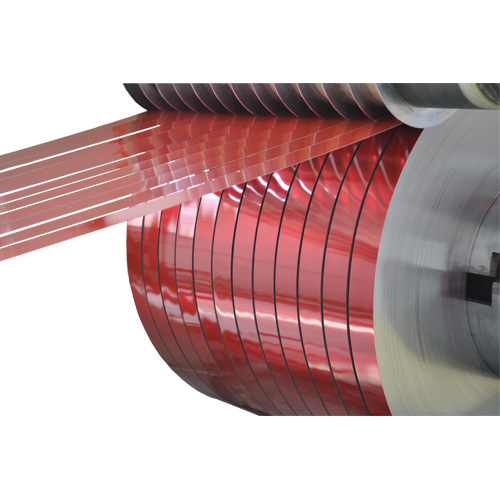

Tin plating: consider the tin plating environment such as concentration and humidity

Oiling: apply DOS oil under normal conditions. To prevent sticking or rusting. However, it is difficult to control the oil point above.

Composition: from bottom to top is the base plate -- iron tin alloy -- tin -- chromium oxide -- oil film

Scan to add WeChat

Scan to add WeChat