What are the advantages of food tinplate packaging

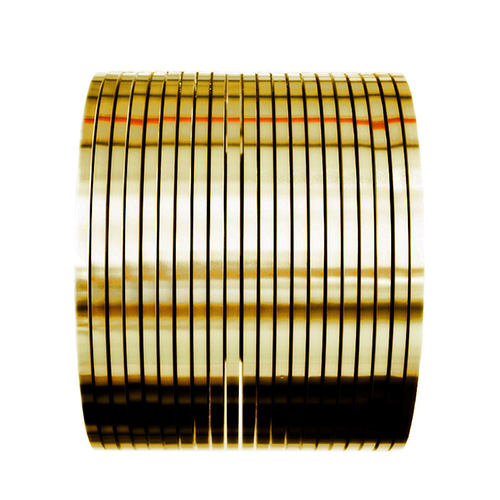

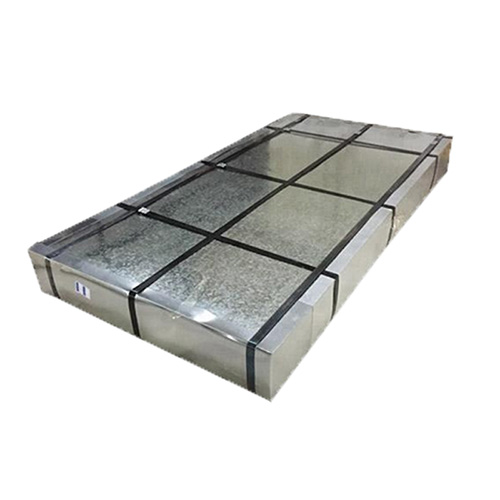

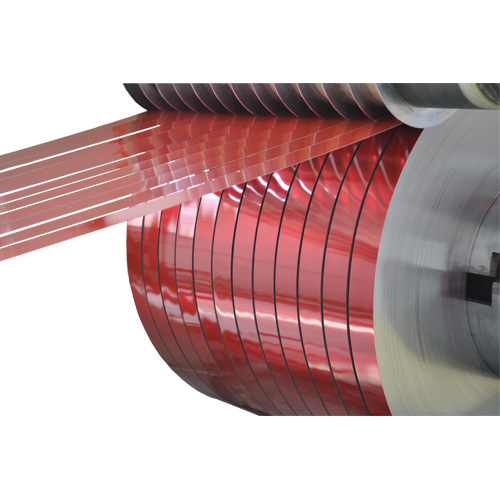

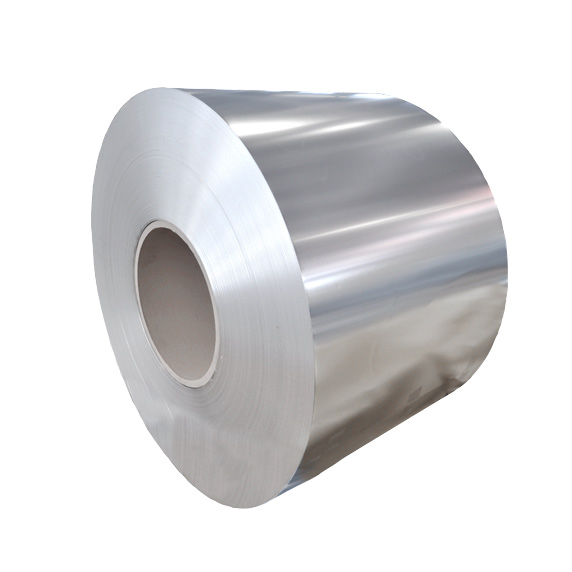

Jiangyin tinplate can has excellent moisture resistance, damage resistance, collision resistance and sealing performance. It is an ideal packaging form for food and tea. The tin cans are generally made of tinplate (tinned steel sheet), the thickness is generally controlled at 0.20-0.32mm, and the tin cans are square, round, and shaped. It can be divided into tea cans, food cans, gift cans, etc; It can be divided into general iron cans (unsealed cans) and sealed cans according to the form.

The products packed in iron cans generally have vacuum packaging bags. This kind of iron cans mostly use external packaging methods, such as moon cake iron boxes, tea iron cans, gift boxes, etc., which can not only increase the sensory effect of the products, but also improve the product transportation. The processing process of iron cans is simple, and deoxidizer can be used to remove the excess oxygen in the cans. The other kind of sealed iron cans has strong sealing performance, such as food iron cans, milk powder iron cans, beverage iron cans, chemical iron cans, etc. The packaged products generally have the characteristics of high oxidation, easy to be polluted, etc. Therefore, this kind of sealed cans has a complete inspection and certification system, with complex manufacturing processes and high cost, and they are mainly packaged in the form of nitrogen filling and vacuum packaging. Therefore, it is recommended to use ordinary iron cans for tea packaging. Their protective performance is not only superior to plastic and paper packaging. And the appearance is beautiful and high-grade. The beautifully designed iron cans are suitable for high-grade tea packaging.

Scan to add WeChat

Scan to add WeChat