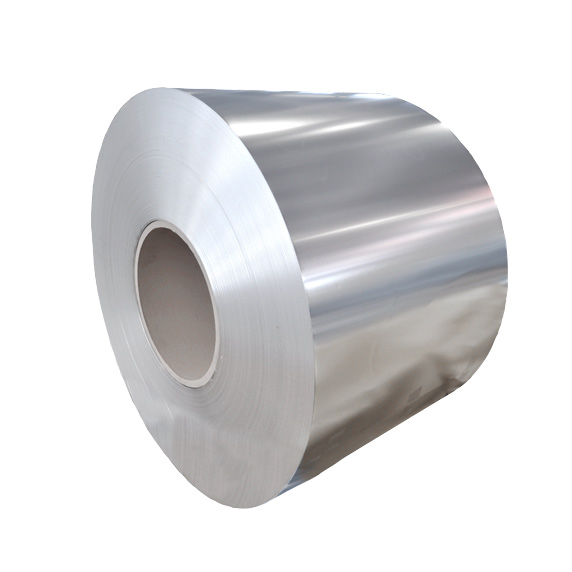

Relevant indicators of tinplate

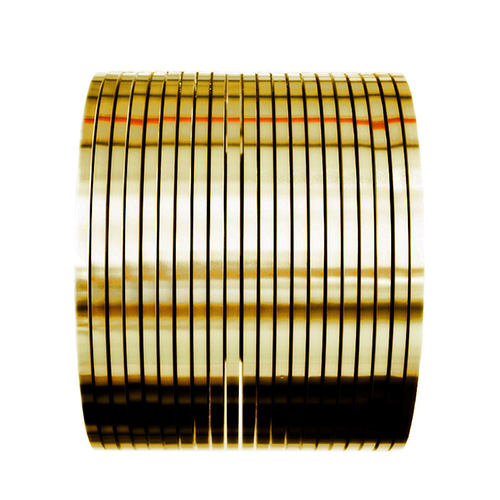

Tin coating

The hot-dip sheet has developed from the 1950s to the current electroplating sheet, and now there is no use of hot-dip sheet in canning in China. To get familiar with tinplate

The historical overview of is as follows:

Tin plating amount of hot dipped sheet:

Code Tin Plating Amount (Both Sides) g/m2 Chinese Name Application Example

H12/12 24

H14/14 28

H15/15 30 1.5 lb tin fruit, vegetable and meat

H17/17 33.6

Tin amount of electroplated sheet:

Code Tin plating amount (per side) g/m2 Chinese name application example

10 # 1.1/1.1 No. 10, except that No. 100 tin is used for canned mushrooms, fruits, etc., generally uses iron below No. 50 tin for iron printing coating processing

25# 2.8/2.8 25

50# 5.6/5.6 50

75# 8.4/8.4 75

100# 11.2/11.2 100

Substrate thinning

This is a well-known wish. At present, 0.15m/m tinplate has been used for capping in China. Some cold-rolled sheet companies have announced that they can produce 0.12mm cold-rolled sheet for cap making industry. Therefore, the secondary cold-rolled sheet with thinner base plate and higher hardness is the development direction of the can (lid) industry.

The list of the tempering degree grades of tinplate in the world is as follows:

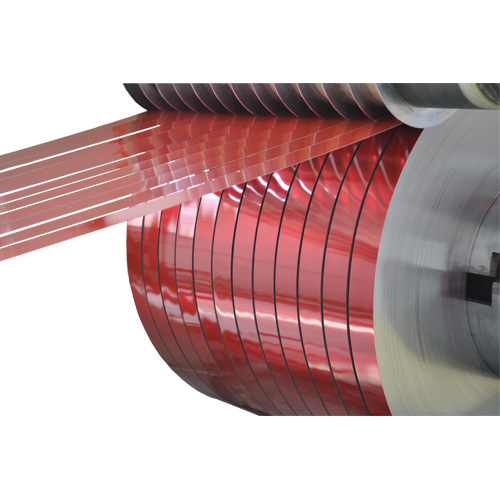

Secondary cold rolled sheet:

Traditional symbol Current symbol HR30T value Tensile strength (MPA) Application

DR8 DR550 73 550+70 round tank body, bottom and cover

DR9 DR620 76 620+70 round tank body, bottom and cover

DR9M DR660 77 660+70 Bottom and cover of beer and carbonated beverage cans

Single cold rolled sheet:

T1 T50 52 330 Extreme deep drawing

T2 T52 52 350 deep drawing

T2.5 T55 55 General

T3 T57 57 370 for general use, no medical treatment for tank body

T4 T61 61 415 is generally used, which is relatively rigid and requires a rigid bottom, cover, shallow flushing tank, etc

T5 T65 65 450 anti warping, requiring rigid bottom, cover and tank body

T6 T70 70 530 is very rigid, and the bottom and cover of beer and carbonated beverage cans

For the same can type, the sheet can be thinned instead of thickened by secondary cold rolling to improve the utilization rate of the sheet.

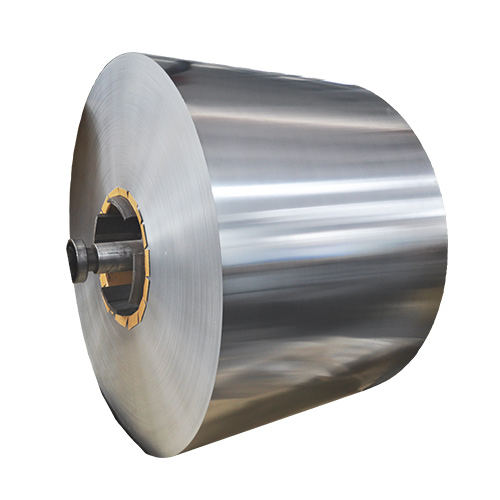

Chromium plated iron

That is, Wuxi steel sheet, which has been in a wandering state since it was introduced to China in the 1980s, has not been widely used until 2000. Even now, the price of ferrochrome plating is more expensive than that of tinned iron. The reason is that the processing performance of ferrochrome plating in iron printing coating is obviously better than that of tinned iron. With the wide use of coated iron, especially in bottle caps, people pay more attention to chromium plated iron, which is characterized by:

(1) The canning processing and corrosion resistance of the base plate are the same as those of the tinplate base plate;

(2) In coating processing, it is not necessary to consider the tin melting problem like tinplate, but higher baking temperature can be used to improve the printing and coating production efficiency;

(3) The adhesion to the film is better than that of tinplate;

(4) Its surface is a very thin layer of metal chromium and hydrated chromium oxide, and the thickness is only about 1% of the tin layer of tinplate. Therefore, it is easy to rust. Therefore, without coating processing, there is no practical value of ferrochrome plating.

(5) Because it is a Wuxi sheet, it saves tin resources and conforms to the development direction of tinplate.

Pre:no more

Scan to add WeChat

Scan to add WeChat