What kinds of metal cans are available

What kinds of metal cans are available

Metal cans are divided according to the number of plates used to make the body and bottom cover It can be divided into three piece cans and two piece cans: the three piece cans include electric welding cans, tin welding cans and bonding cans. The two-piece can is a punched and drawn can made of aluminum plate or tinned iron plate. The body and bottom of the can form an integral whole. The cover of the can is sealed with double crimping.

At present, beverage cans are easy to open. Easy to open cans can be divided into pull ring type (pull out the pull ring when opening cans) and button type (press the pull ring when opening cans) according to their opening methods.

(1) Can making automation equipment Three piece can

1. Tin welding tank can making automation equipment

It is composed of 3 parts: tank body, tank cover and tank bottom. The tank body is provided with a joint, and the outer side of the joint is welded with tin to seal it; The can cover and bottom are connected with the can body by double crimping method, and the sealing glue applied on the inside of the can cover and bottom edge is used to maintain their sealing.

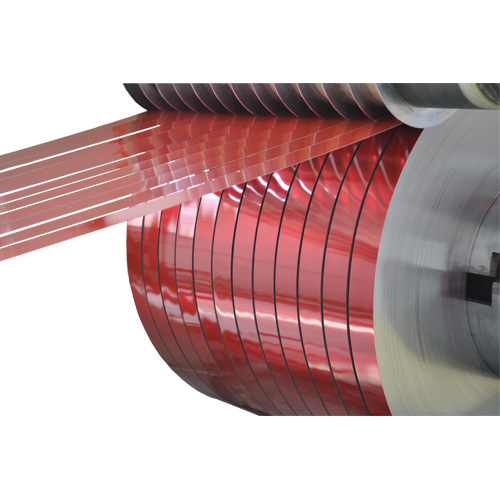

Tin plating sheet and soldering tin used for canning will consume precious metal tin, and tin lead will lead to lead purification of canned food from empty cans. In order to protect the health of consumers, especially infants, the amount of lead brought in from empty cans in beverage cans will be limited. Solder cans have been eliminated and replaced by three pieces of electric welding cans. Can making equipment

2. Electric welding tank can making automation equipment

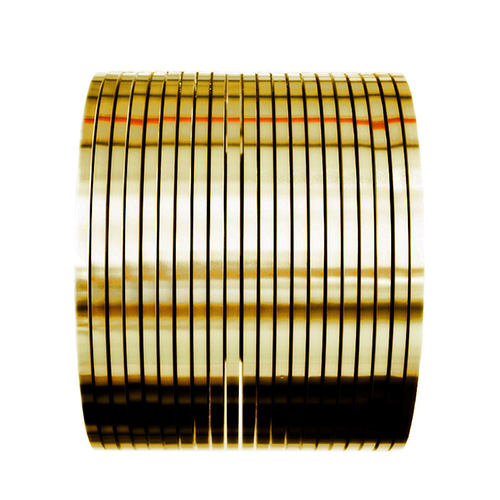

Unlike tin cans, it does not have to solder High frequency resistance welding is adopted to directly weld the overlapped joints of the tank body. Can making information is tinplate. Judging from the overlapping width of the seam of the can body, the metal data consumed by the seam of the electric welding can body is the least among the three pieces of cans.

(2) Can making automation equipment Two piece can

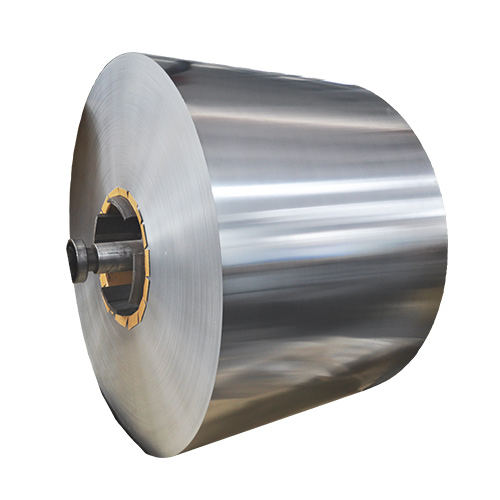

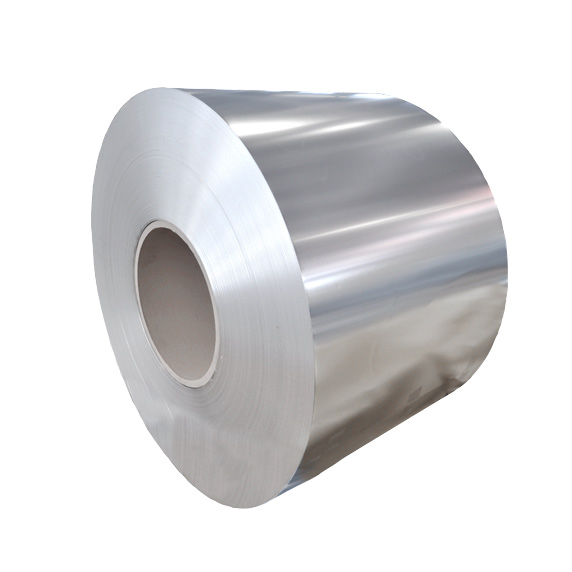

At present, the two-piece can used for beverages is DI can It is composed of two parts, namely, the jar body and the jar cover. DI tank uses aluminum plate or tinplate as data, and adopts the tank wall thinning and stretching technique to make it undergo qualitative changes in thickness, hardness and other aspects after rolling. So that it has various characteristics. DI cans are thin and light, with good internal pressure resistance. They are suitable for carbonated drinks and beer.

Scan to add WeChat

Scan to add WeChat