Detailed explanation of the printing process of tin cans

The tin can printing process is mainly divided into several major processes, such as color separation, proofing, determination of drawings, printing, determination of printing materials, coating, etc. Next, we will introduce the tin can printing process

1. Color separation is an important link in the printing of metal products: at present, domestic and foreign iron printing equipment are mainly monochrome printing presses and two-color printing presses, and the first is to ensure that the color function of tin can printing matches the role of the original provided by satisfied customers In order to prevent the influence of overprint prohibition, scratches, significant color difference, less bright colors, and many defective products in multi-color printing, spot colors are often used to replace multi-color overprint in tinplate printing, such as Pantone color Together, we will focus on the return dot and coarse screen line, so that the reduction of the number of points on the total area of the screen will reduce the number of printing dots and increase the number of printing dots, so as to achieve a better printing effect

2. Printing and proofing: First, check the color separation film and analyze and master the quality of tinplate products in advance In the proofing process, if we want to keep the color separation sample as the reference in the printing process control, we can make the printing quality stable and the color can truly reproduce the sample admitted by the customer Tianjia Cannery warmly reminds us that we need to process tinplate products and put them into the contents, that is, molding test. For example, food tins should be tested for their sealing, shelf life and freshness

3. Drawing determination: the iron printing drawing shall determine the three elements of sheet positioning rules, product placement methods and cots used for product coating The positioning rules of tinplate refer to the direction and scale of seaming and leaning, which is the basis for printing; The product placement method is different depending on the nature of the product

4. Printing: For the printing of cans and lids, when making lithography, most of the same pictures are made into negative pictures or positive pictures in groups according to the determined product drawings, and the continuous printing machine is used for exposure plate making

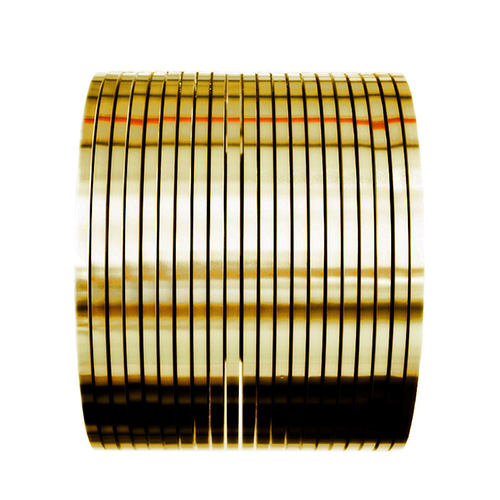

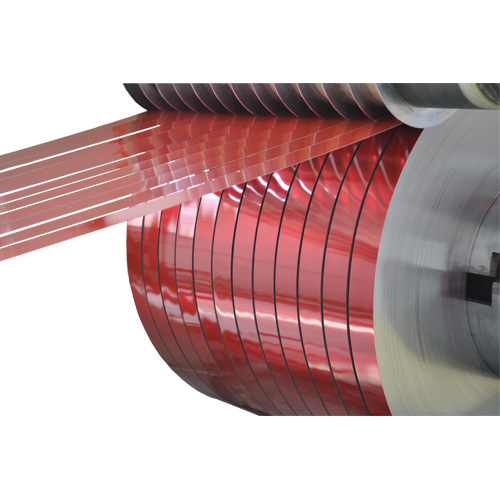

5. Determination of printing materials: because different product uses and forming equipment have different process requirements for the thickness, tin layer, hardness and annealing method of tinplate, we should determine the above elements according to the nature of the product, which should not only meet the printing requirements, but also meet the requirements of can making, punching and other requirements, and determine the printing surface. Tianjia Canmaking Factory reminded that the general tin can printing is the physical property of using water and ink to repel each other, depending on the printing pressure, It belongs to the principle of lithographic offset printing to transfer the printing plate image and text to the iron box through the blanket

Scan to add WeChat

Scan to add WeChat