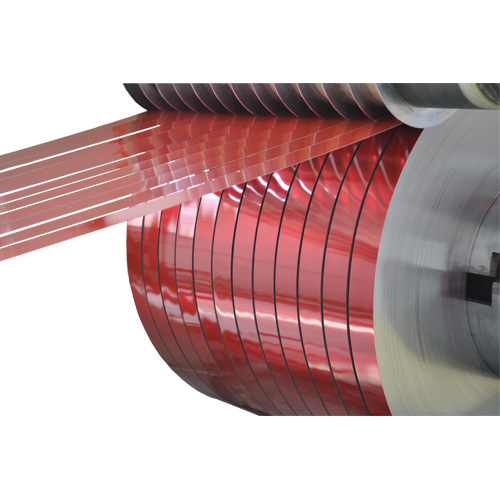

Printing Tinplate

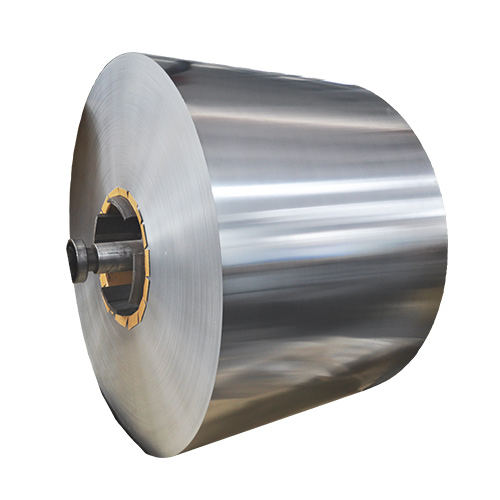

Tinplate Coils/Strips

Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solderability, and weldability. Tinplate is used for making all types of containers such as food cans, beverage cans, 18-liter cans, and artistic cans. Its applications are not limited to containers; recently, tinplate has also been used for making electrical machinery parts and many other products.

Product Details:

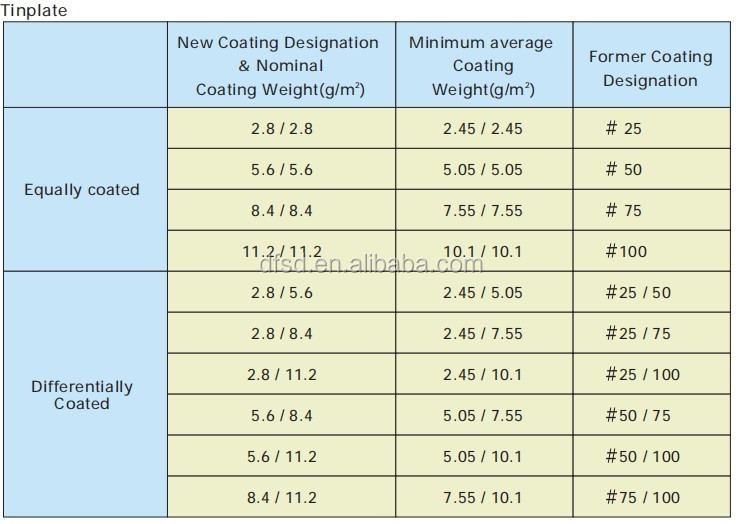

The tin coating weight is determined in accordance with specific end use applications. Tinplate with a heavy coating weight is used for making cans that require a high corrosion resistance or those used bare. Tinplate with a light coating weight is used for making cans that do not require so high a corrosion resistance or those used after painting or printing.

Differential Markings

A white line (differential marking) is painted along the edge of a differentially coated product in order to clearly indicate that it is differentially coated, and "D" is added after the coating designation symbol for the marked side (e.g., 2.8D/5.6). With regard to other types of differential markings, please consult us.

Standard for Temper:

Surface finish:

Pre:no more

Next:Printing Tinplate

Scan to add WeChat

Scan to add WeChat